CAMAC offers the following product lines below.

Learn About Our Valve Brands and Product Lines

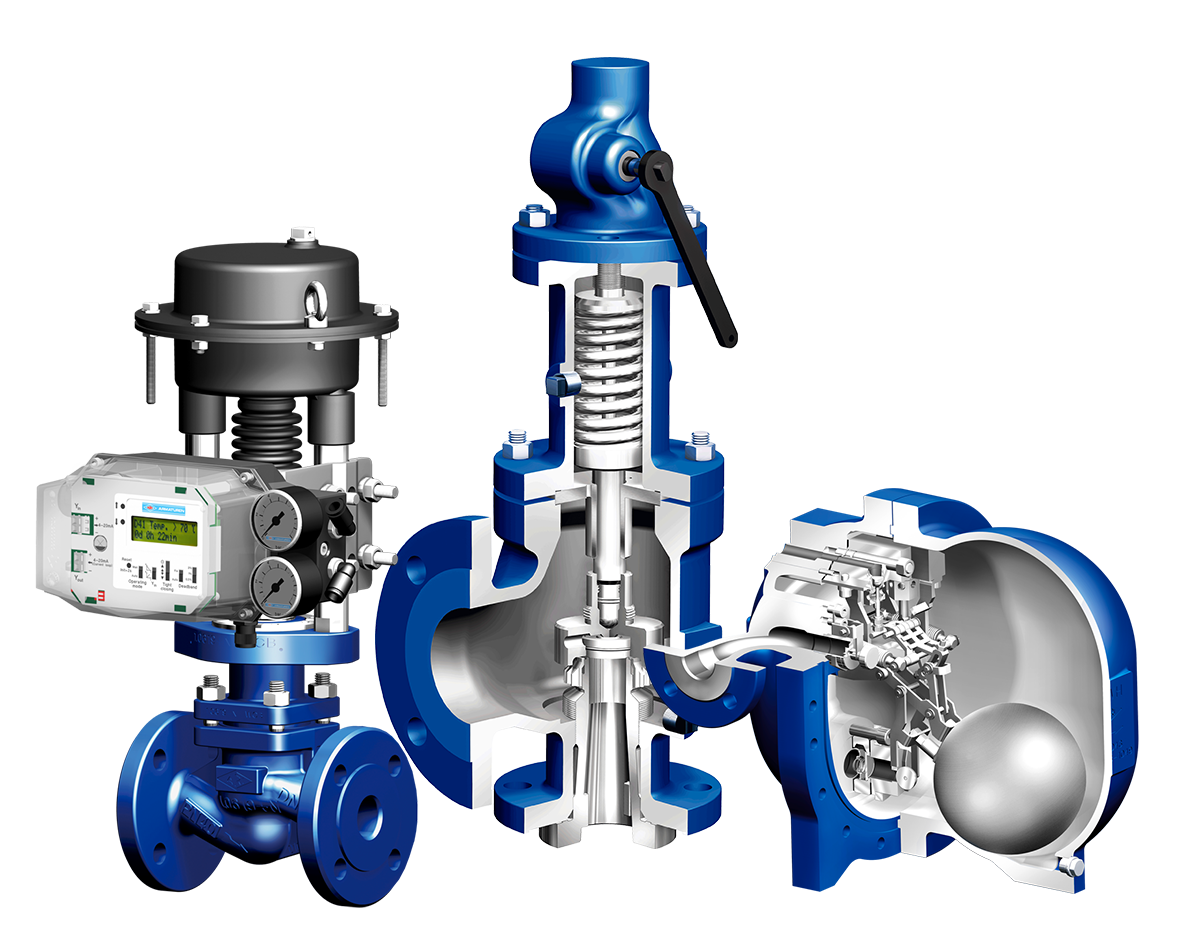

- Expert CONTROL: Straight-through or 3-way control valves with electric or pneumatic actuation, pressure control valves, & temperature control valves

- Reliably tight ISOLATION valves: Triple-offset, double-offset, or soft sealing butterfly valves, globe valves, & check valves

- Your partner in SAFETY: Semi- or full-nozzle safety relief valves & change-over valves

- High performance STEAM solutions: Steam traps (mechanical, thermodynamic, & thermostatic) in traditional, universal, or compact multi-valving designs, valve manifolds, pump traps, & mechanical pumps

- Complete packages for your steam SYSTEMS: Heat exchanger packages, condensate return systems, steam trap stations, flash steam systems, & pressure reducing packages

Hy-grade valves are constructed using premium materials such as stainless steel or brass, ensuring durability and long-lasting performance. These valves are suitable for a wide range of industries and applications including oil and gas, water treatment, chemical processing, and more. They are designed to withstand harsh environments and corrosive materials, making them ideal for use in corrosive fluids or gases. These valves offer precise control over the flow of fluids or gases, allowing for accurate and efficient operation. Featuring a simple and robust design, these valves are easy to maintain and repair, minimizing downtime and reducing operational costs. These valves can handle high-pressure and high-temperature applications, ensuring reliable performance even in extreme conditions. Hy-grade valves are available in a variety of sizes, allowing for customization and flexibility in meeting specific project requirements. With tight seals and advanced sealing technologies, Hy-grade valves are designed to prevent leaks and ensure safe and efficient operation. The valves are engineered to provide smooth and precise operation, resulting in high flow rates and minimal pressure drop. Hy-grade valves meet international standards and specifications, ensuring quality and reliability in all their products.

The message from our prestigious customers is clear "Provide us with superior and innovative quality valves and respect promised delivery dates". Trueline clearly understood the message. Each year Trueline invests in research and development, highly qualified personnel, and equipment, to ensure the supply of the highest quality valves with deliveries that are unmatched by the competition. Furthermore, our proprietary custom valves and technical expertise satisfy the most severe customer applications.

A continuous improvement system monitors and ensures that we never lose sight of what is important to our customers.

Our high standards extend beyond our product line. We have gained and maintained the respect of our customers by conducting our business in a forthright, open and honest manner. High quality products provided by an organization with a reputation for integrity is what our customers expect, deserve and receive from Trueline.

These valves come in different types, such as cooling only, heating only, or combination valves that can handle both heating and cooling. - VRC valves are typically controlled by a microprocessor that monitors the temperature in each zone and adjusts the flow of refrigerant accordingly. - One type of VRC valve is the electronic expansion valve (EEV), which uses an electronic motor to control the refrigerant flow. Another type is the thermostatic expansion valve (TXV), which uses a temperature-sensing bulb to regulate the flow. - Compared to traditional HVAC systems, VRC valves offer greater energy efficiency as they allow for precise temperature control in different zones, reducing energy waste. - VRC valves also offer more flexibility as they can be easily reconfigured to adapt to changes in building usage or layout. - However, VRC valves can be more expensive to install and maintain compared to traditional HVAC systems. - VRC valves are also more complex and require skilled technicians for installation and maintenance. - It is important to regularly check and clean VRC valves to ensure they are functioning properly and to prevent any potential issues. - Overall, VRC valves offer improved comfort, energy efficiency, and flexibility in HVAC systems, making them a popular choice for commercial and residential buildings.

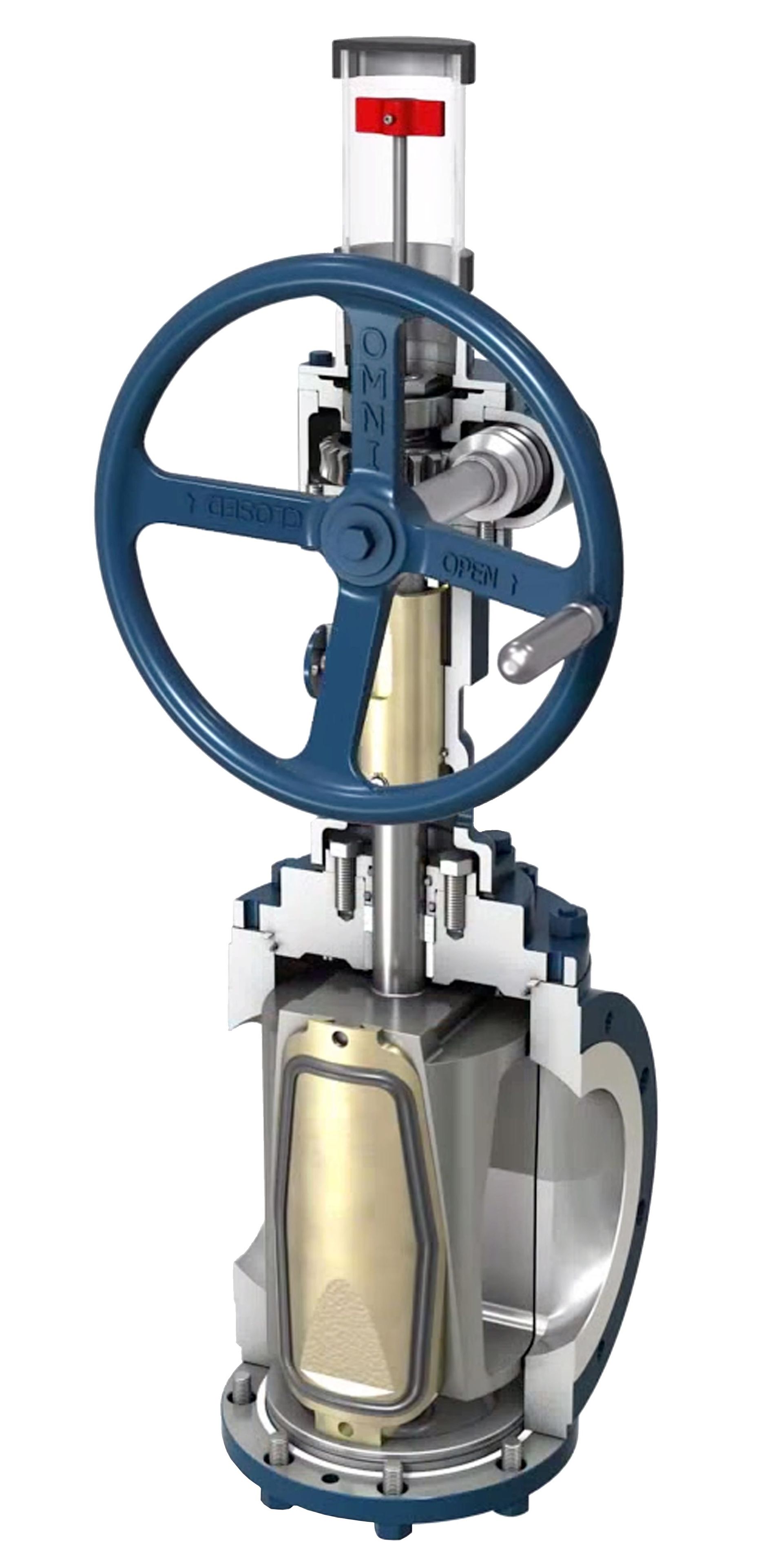

OMNI VALVE

Omni DBB/DIB Expanding plug valves are high integrity, retracting slip, non-lubricated Expanding plug valves. Designed for applications where positive shut-off, and verifiable zero leakage is essential. Ideally designed for Product Isolation, Blending, Metering, Custody Transfer, Fueling, Terminal, and Storage applications. Omni Expanding Plug Valves are designed for applications that require positive shut-off, Verifiable zero leakage and Double block and bleed(DB&B) or Double Isolation and Bleed (DIB) capabilities are essential as now defined by API 6D standards.

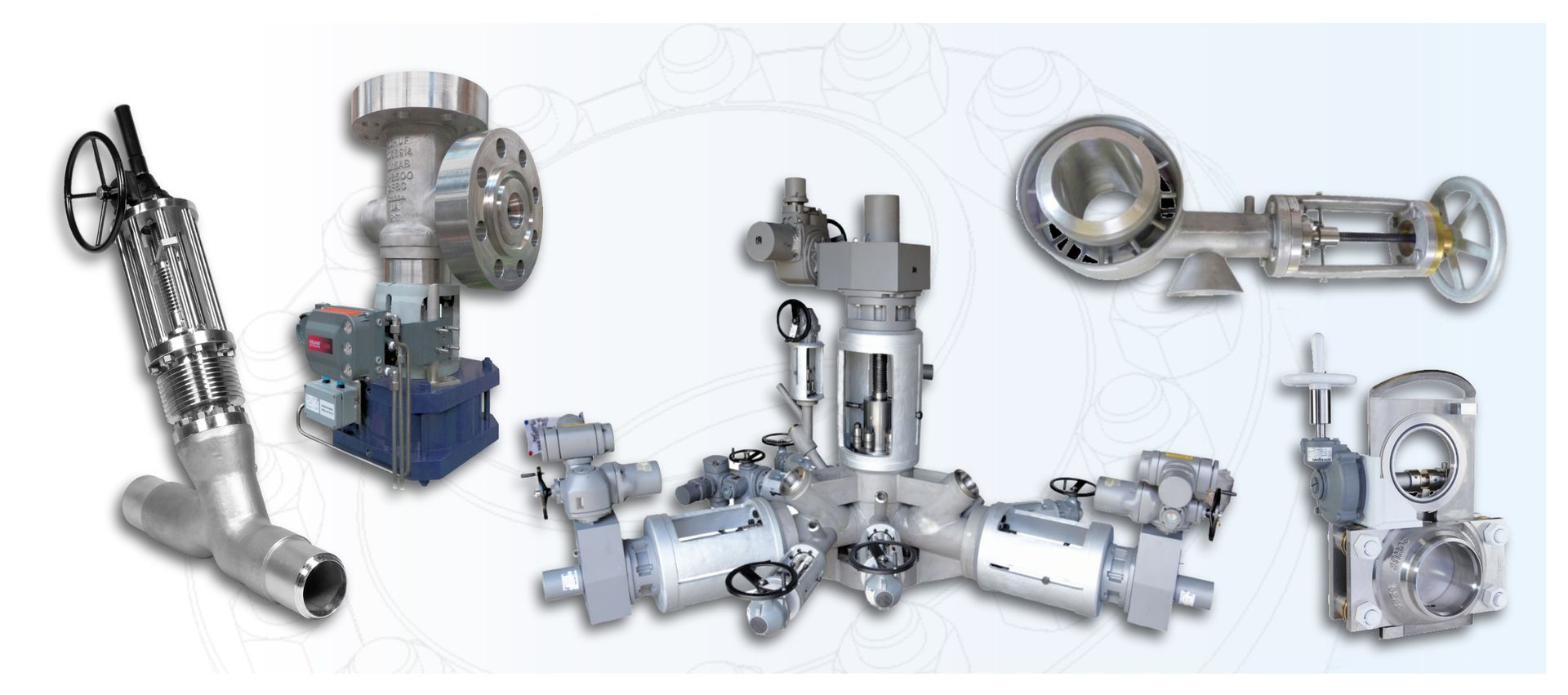

The company has design and manufacturing centres in Germany, the United States, the United Kingdom, Ireland, India and Italy. SchuF is the original inventor of the lift-plug and bottom-outlet types of valve, and has delivered over one million valves during its 100 year history to a wide variety of industries in over 60 countries worldwide. SchuF valves can be found in a wide cross-section of industries and applications involving the handling of critical or severe processes, such as is in the chemical, refining, pharmaceutical, plastics and polymers, mining, aluminium, and power industries.

Dyna-Flo

A business unit of Curtiss-Wright Valves Division. With over 30 years' experience, we contribute to safer and more reliable plant operations worldwide by providing control valve systems, technology, and engineering that enables our customers to perform efficiently and achieve expected results.

Dyna-Flo is your Trusted Partner to help improve plant safety, minimize downtime, and eliminate production disruptions with our safe and high performance control valves. We design, manufacture, and supply a variety of control valve systems that meet our customers most demanding applications and solve operational challenges. Dyna-Flo provides engineered control valve systems to help customers achieve safe and reliable operation, while reducing total cost of ownership

HYTORK

The Hytork XL-series rack & pinion actuator is modular in design and is field convertible from double-acting to spring-return and vice versa. The 12 actuator sizes are designed to automate the most popular quarter turn valves like ball, butterfly and plug valves. Hytork XL actuatos have numerous features that add reliability. Its rugged heavy duty, all coated body is made from a high strength LM25 aluminium casting designed to prevent damage from dents, shock or fatigue

JC Valves

JC Valves are designed and produced to meet the major international standards and we take great care and put a lot of emphasis on QUALITY, which provides our customers with a total guarantee and trouble free operation of their process. And in addition, we take great care to make our facilities and our products Environment friendly

We began more than 50 years ago as manufacturers of ball valves under the name of JC Valves, whose essence and values we still retain.

We have grown and evolved to become part of a large group: TTV-JC Valve Group, also thanks to the trust and loyalty of our customers, who with their suggestions motivate us to innovate and invest in new products, machinery and resources to carry on improving day by day. This evolution also involves a transformation in some areas with the intention of adapting to your specific, changing and current needs and thus continue to guarantee an unmatched service.

Today we are a great team that is present in many countries to offer you technical solutions in any sector, because their commitment is ours, anywhere in the world.

ACTREG

The all-in-one ACTREG interface is a “must have” for the modern automation valve business. Ideal for work, use the ACTREG interface to calculate torques with and without safety factors, and do your own configuration with

ACTREG actuators. You can also convert any unit of measurement, dimensions, torques, temperature and materials equivalences from most common standards

The sleek easy-to-use interface makes actuator and torques calculations quick and easy. The user-friendly screen interface lets you see at-a-glance, so you can convert or calculate quickly while you are on the go.

We have also included some quick information about ACTREG, and all their product range. A very useful interface made by ACTREG. Anytime, anywhere and in any situation.

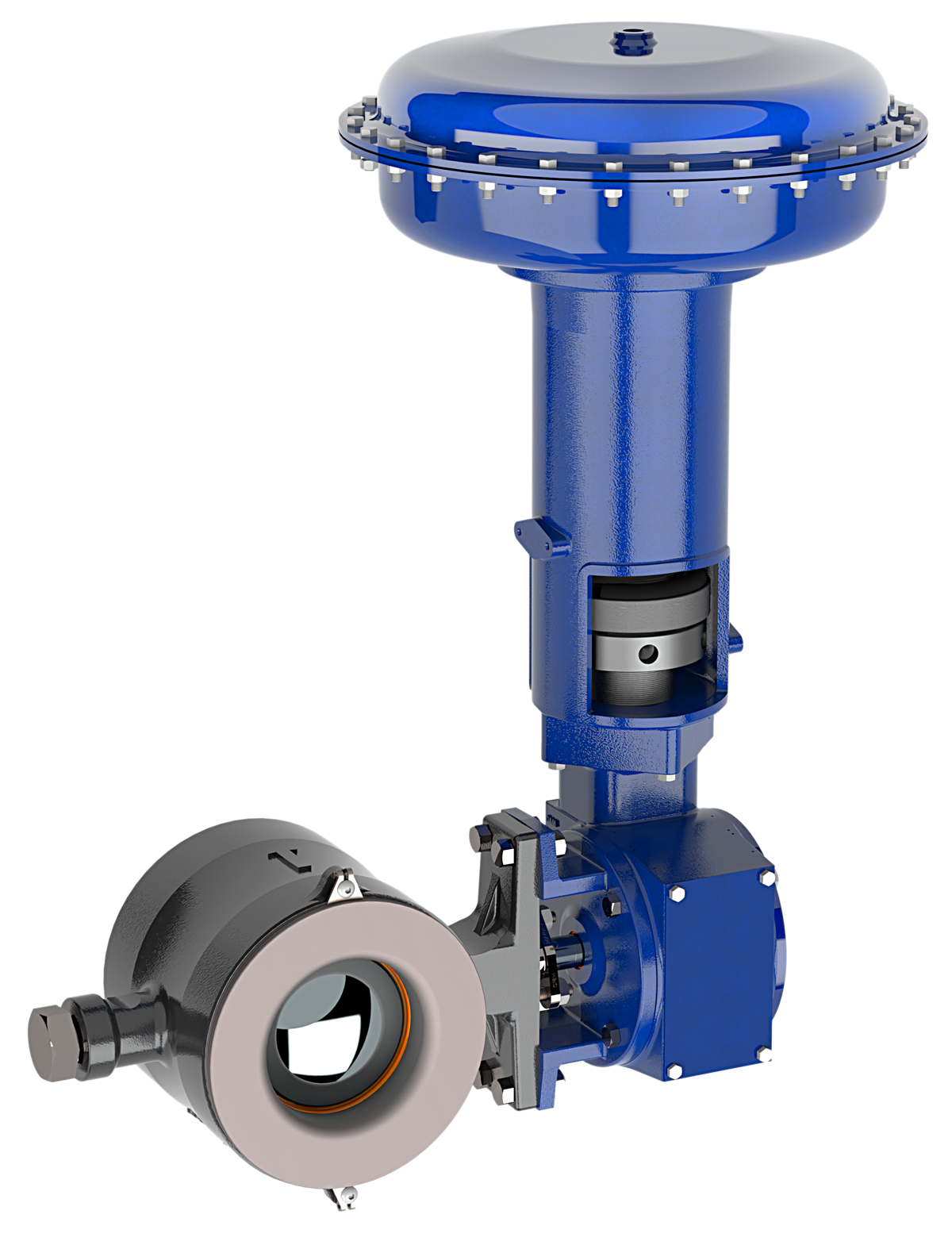

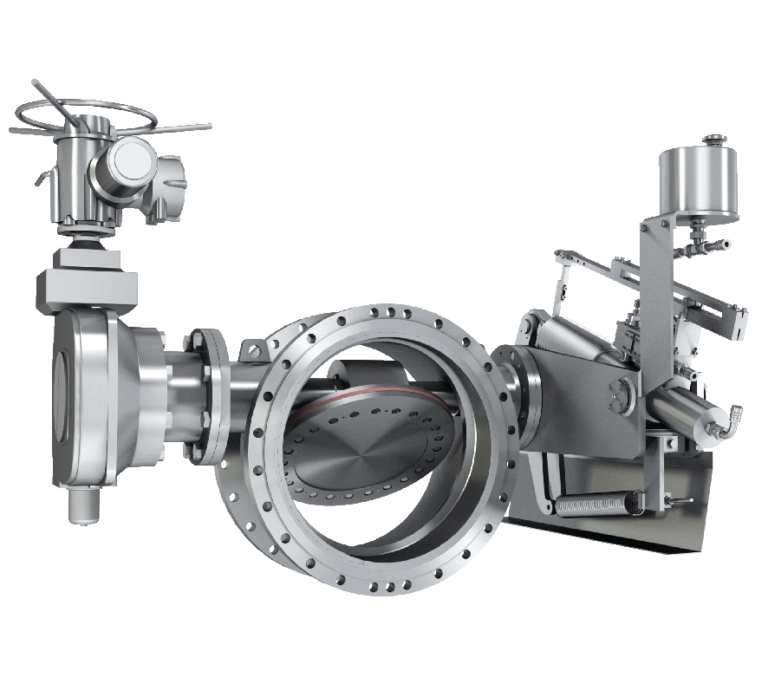

Adams Valves

A manufacturer of quality German-engineered rotary isolation, control, and check valves. Inventor of the triple eccentric (triple offset) butterfly valve which offers reliable and high integrity sealing performance in demanding environments such as high temperatures, cryogenics, steam, hazardous gases, fast closing emergency shutdowns, and nuclear safety systems. Industrial grade triple duty valves combine control, tight shutoff and check valve functions into a single valve package allowing for reduced piping space and pressure loss as compared to separate valves along with a controlled shock free closure.

QTRCO Actuators

For over 25 years QTRCO has been a leading manufacturer of quarter turn actuators. Patented design features that reduce internal friction and wear allowing for a more compact and balanced design when compared to typical Scotch Yoke actuators. QTRCO’s Inward captured spring design for single acting actuators allows the piston seal to be easily “inline” replaced without removing the actuator from the valve. With their symmetric top and bottom plates the failsafe rotation can be easily reversed without disassembling the actuator simply by flipping the actuator over and remounting. QTRCO actuators excel in corrosive, high cycle, high speed applications, are made in the USA, and are covered by a 3-year manufacturers warranty.

Do you have questions? Call our team at (904) 292-4200.